— by Jon Lybrook, Lead Printmaker & Owner, Intaglio Editions LLCI used to do alot of summer and holiday art fairs about 10 years ago, but stopped due to the amount of work I was doing with other artists, photographers, and printmakers. That plus internet marketing and consulting work meant there just wasn’t time. We continue to produce custom, high-quality intaglio plates and prints for photographers, printmakers and other small businesses world-wide, but not like we were in the early 2000s. |

| The current state of the economy here in the United States has me considering showing my own work, and that of the artists I contract with, at summer art shows again. If you are a traditional intaglio printmaker like me, perhaps you’ve been considering the same. If you are participating in art fairs already, you know summer is a busy and back-breaking time for many artists who registered for art shows back in April, when most submissions deadlines end. The good news is, you have plenty of time to start preparing for the summer art shows happening in 2026! |

| Researching, preparing, and showing at quality outdoor art festivals can take alot of time, planning, hard work, and money, but if they are effective for you, and you are committed to doing them every year, they are an excellent way to gain a new, growing audience of fans, supporters, and repeat buyers. |

|

Need high-quality, professional art prints to help promote your fine art drawing, painting or photography?Let Intaglio Editions Help Your Art Business Thrive! |

Author Archives: Jon Lybrook

Artist Interview with Paul Richards – April 2025

Paul Richards, guitarist and co-founder of California Guitar Trio, is also a fine art landscape photographer. In this April, 2025 interview Paul talks with his printmaker, Jon Lybrook, about his new print releases, the upcoming CGT Tour, the trials and challenges of being a working musician while making landscape photographs from around the world.

Important Links:

Pre-Holiday Sale – Get 10-40% off most prints now thru 12/18/24!

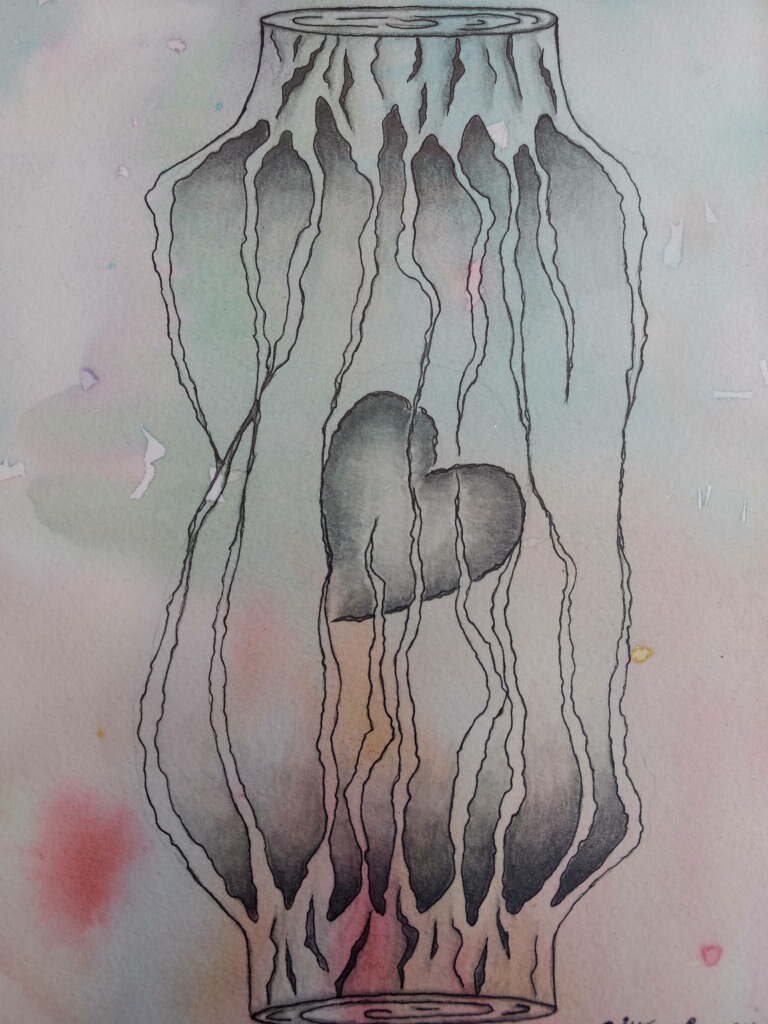

Donating Gently Used, Fine Art Supplies to Schools

We used to wonder what to do with by-products of expensive editioning projects, like used backing sheets of fine art paper, and unused inks and paints…

The solution of what to do with them was easier than we thought. Through the help of a friend, we were able to reach out to teachers and donate them to our local schools!

Over the past 5 years Intaglio Editions LLC has donated thousands of dollars worth of gently used Stonehenge 250 gsm, 100% cotton rag paper to classrooms around Colorado. This paper is a something we use as backing sheets when printing photogravure prints. After they have gone through the press a few times, the paper fibers have been pressed down to the point where the paper starts to crack under pressure, so they are no longer usable to us.

Over the past 5 years Intaglio Editions LLC has donated thousands of dollars worth of gently used Stonehenge 250 gsm, 100% cotton rag paper to classrooms around Colorado. This paper is a something we use as backing sheets when printing photogravure prints. After they have gone through the press a few times, the paper fibers have been pressed down to the point where the paper starts to crack under pressure, so they are no longer usable to us.

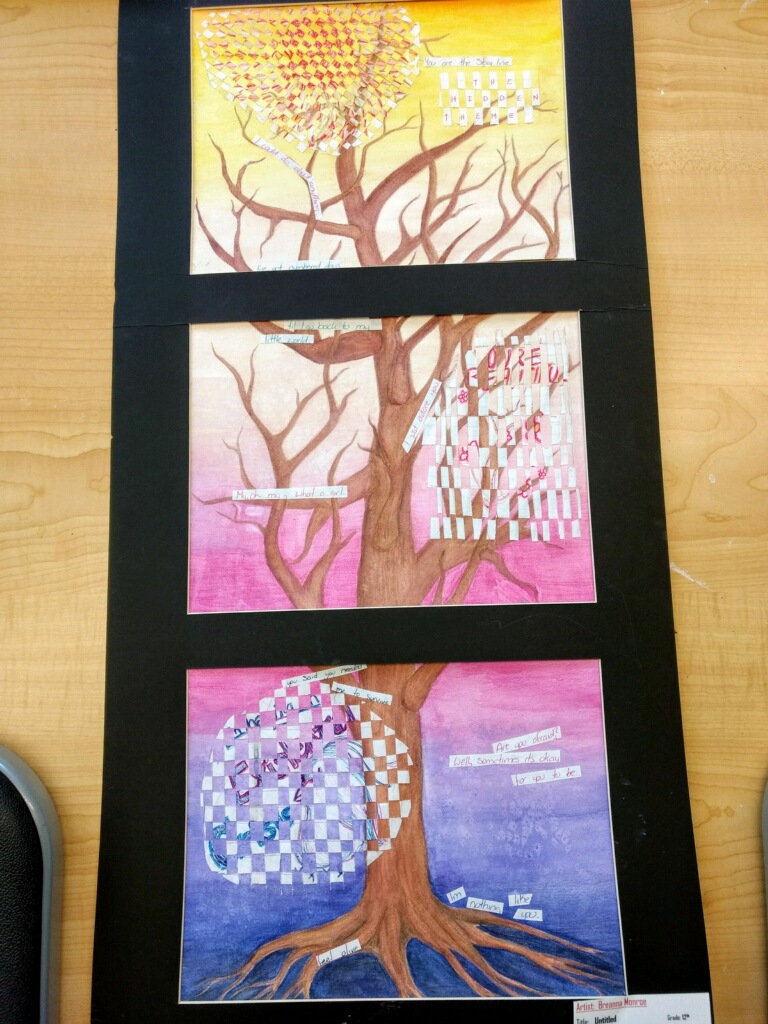

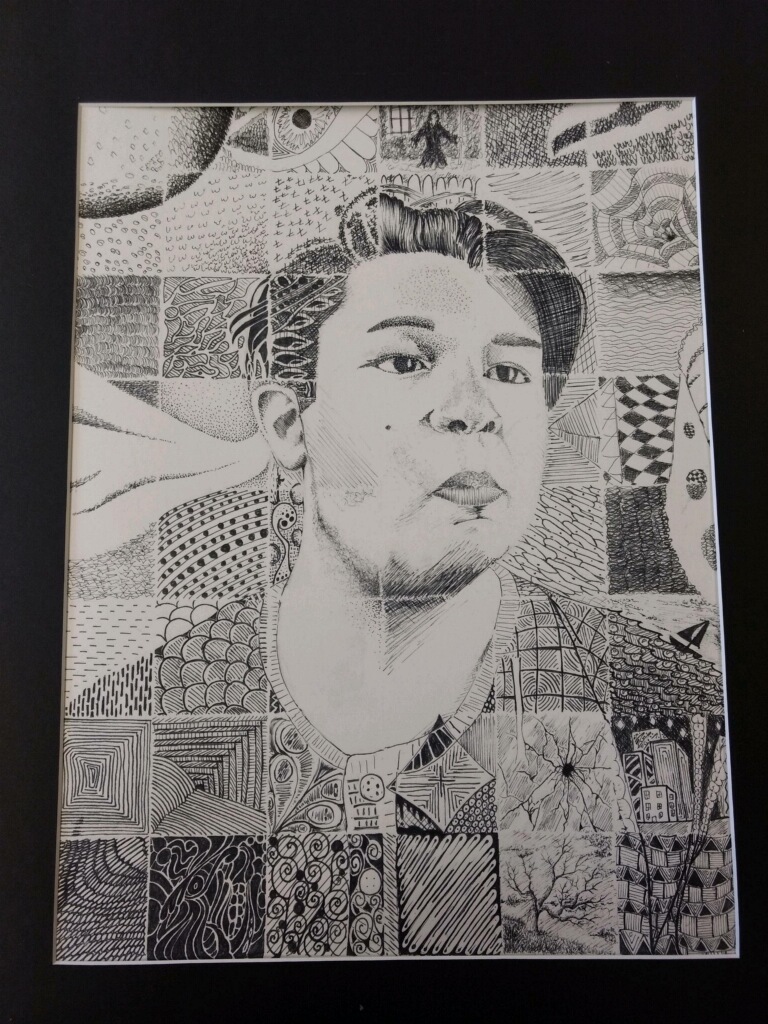

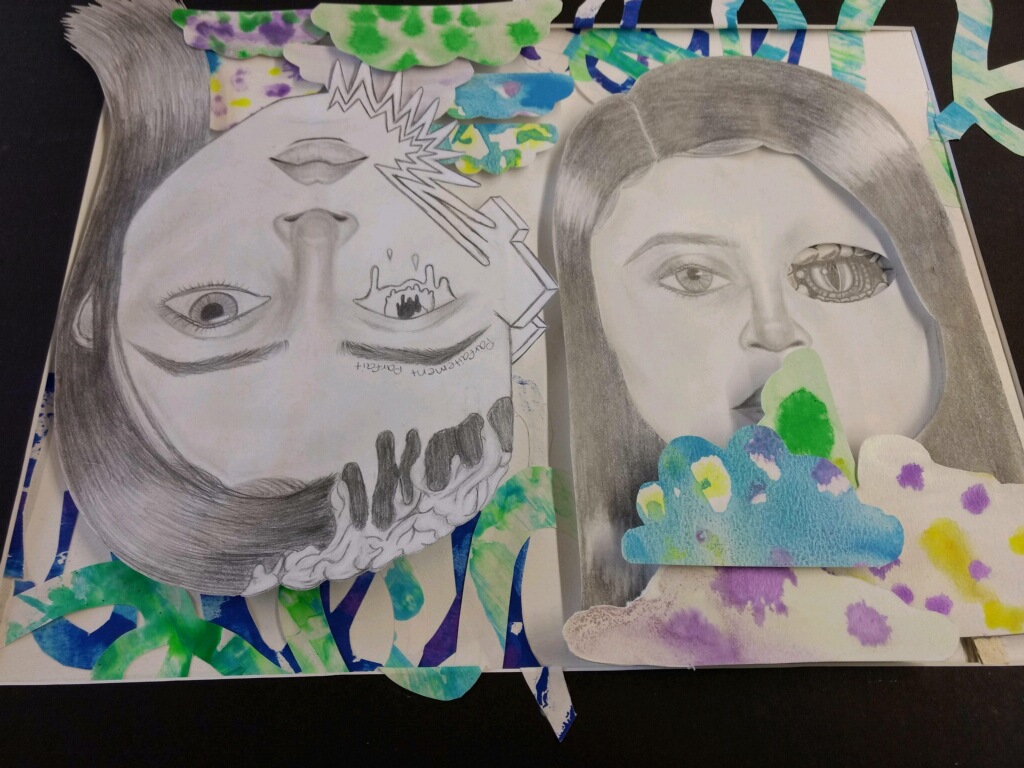

Our annual donation of quality art paper gives students the opportunity to work with professional art materials, often for the first time. Colorado schools benefiting include: Mapleton Expeditionary School of the Arts (MESA) (public high school grades 9-12), Mapleton Public Schools #1. Thanks to art teacher Erica Wernsmann-Loppnow (Mapleton/MESA), and Silverthorn Elementary teacher Katie Irvin for sharing their stories and student’s exceptional artwork, below.

Do you have surplus paper or fine art materials to donate to art students in Colorado? Please contact them directly using the links above, or let us know!

“[We teach] a mix of student work, ink, gelli print, paper weaving, watercolor, pencil. We really try it all and encourage experimentation and complexity and pushing the capabilities of materials.” – Erica Wensmann-Loppnow

“The paper you have given us is so lovely. I really does elevate their work it’s a great opportunity to talk to kids about reusing as well as quality of paper and what we use it for”

– Katy Irvin, Art Teacher, Silverthorne Elementary School, Summit, CO.

“[From the paper donations] we use every piece, nothing is wasted. And kids definitely feel the difference using high quality paper.” – Erica Wensmann-Loppnow

“[From the paper donations] we use every piece, nothing is wasted. And kids definitely feel the difference using high quality paper.” – Erica Wensmann-Loppnow

Have quality art supplies to donate as well? Contact your local elementary school or contact the school board to ask about what donations are needed in your area. New or gently used art paper, canvas, and non-toxic paints are usually welcomed.

Have quality art supplies to donate as well? Contact your local elementary school or contact the school board to ask about what donations are needed in your area. New or gently used art paper, canvas, and non-toxic paints are usually welcomed.

Calendering the Paper

Our last post about the top 2023’s Best 5 Printmaking Tips as concerned paper calendering prompted alot of questions on our website! So, I thought I should elaborate a little on the practice and value of calendering paper here at Intaglio Editions Fine Art Prints!

The verb ‘calender’ comes from the root word ‘cylinder’, which is what is used to make paper flat. In our case, we use the steel-faced drum of an intaglio printing press! All paper is calendered to a certain degree of flatness from the paper mill.

However heavy-weight art papers often have added texture to their surface. Hahnemule Copperplate 300 g/sm is one such paper. Such texture can add noise in the continuous tones of photogravure prints, so we stretch and press the paper even flatter to address this.

At Intaglio Editions, we soak paper for at least an hour. We then blot the paper between towels, and use a drafting brush to remove any particles or hairs that may have gotten transferred to the paper. The paper is then laid printable side down on the press bed against a smooth plexiglass, and covered with two similar sheets of heavy-weight paper. Paper is run through the press at least 2 times at hand-tight pressure. We then remove the paper and cover sheets, wipe down the bed, and register the plate. The plate is typically printed at slightly less than hand-tight pressure on the press bed.

Some finer papers, such as quality Japanese gampi, will not be made any smoother through calendering. These papers should be ‘ready to go’ straight from the vendor with no calendering needed.

When printing photogravure quality plates, also be sure to use 2-4 backing sheets to help ensure the pattern from your blankets doesn’t interfere with your continuous tones. Also remember to use pressed wool blankets – never woven – as these can leave a more noticeable pattern in continuous tone areas of the print).

Check out this excellent demo video on calendering paper on an intaglio press by Jeffrey Dell.

5 BEST Intaglio Printmaking Tips of 2023 from Intaglio Editions

As we close down another year, it’s a good time to pause and examined what we’ve learned. Over the years we have come up with some effective ways to increase print quality and efficiency when printing steel-backed, polymer photogravure plates. Here are the Top 5 tips we use all the time when printing your Intaglio Editions polymer plate:

Jon Lybrook at Nils Borch Jensen Studios in 2018 in front of a large Keith Haring print.

- Use heating pads available from drug stores to warm your plate before applying ink. The same pads can be placed under the glass ink slab. Heating the ink makes it looser and allows it to flow into the pits of the plate better, providing better density and richness. This is especially vital in winter months.

- Some projects go on longer than the ink can stay fresh. Weigh your ink when mixing combinations of modifiers and inks to ensure a consistent mixture every time.

- Always calender your paper before printing photogravure! This pre-stretches the paper, and allows for more consistent results. It is also necessary when printing multiple plates on the same sheet to prevent overlap.

- To secure registration of your plate, lick a clean finger. Now put three dots of spit from your finger to the middle of the back of the plate. Moisture behind the plate helps prevent the plate from pivoting or sliding during the printing.

- Clean your plates using a gentle solvent, like SoySolv2 after use, but avoid over-cleaning or scrubbing polymer photogravure plates. Cleaning plates too often or roughly will lead to an early loss of fidelity.

Questions? Contact us for a free consultation!

What is an Open Edition vs. Limited Edition in Fine Art Prints?

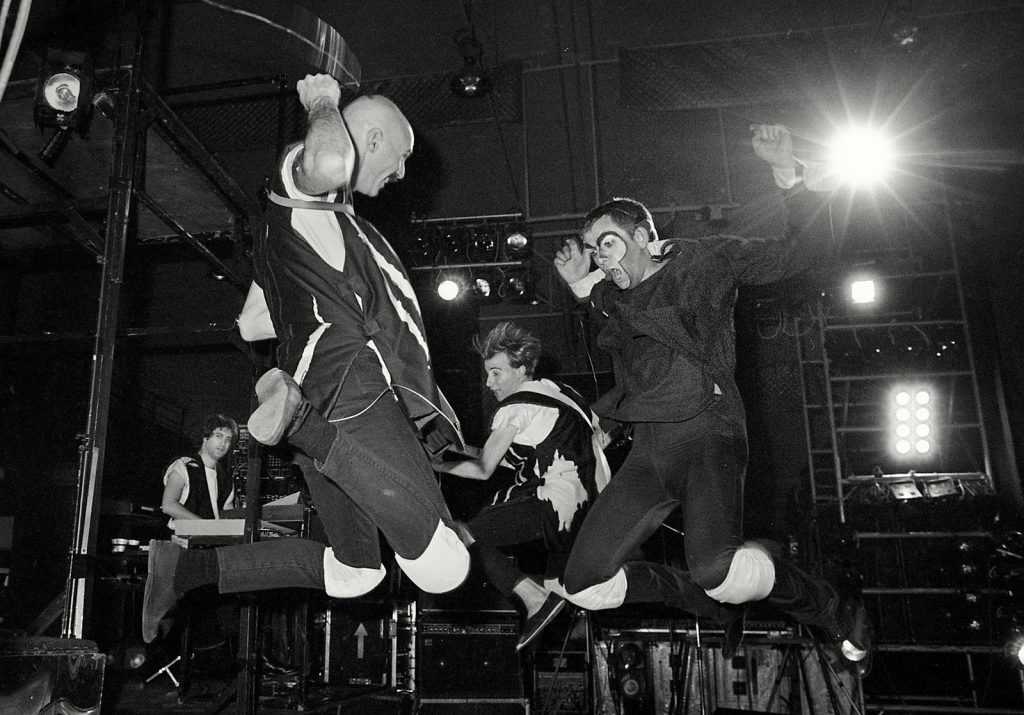

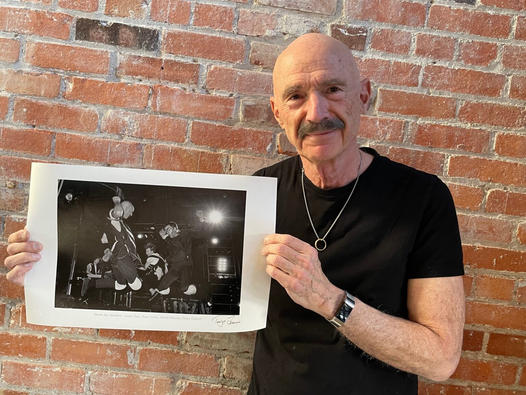

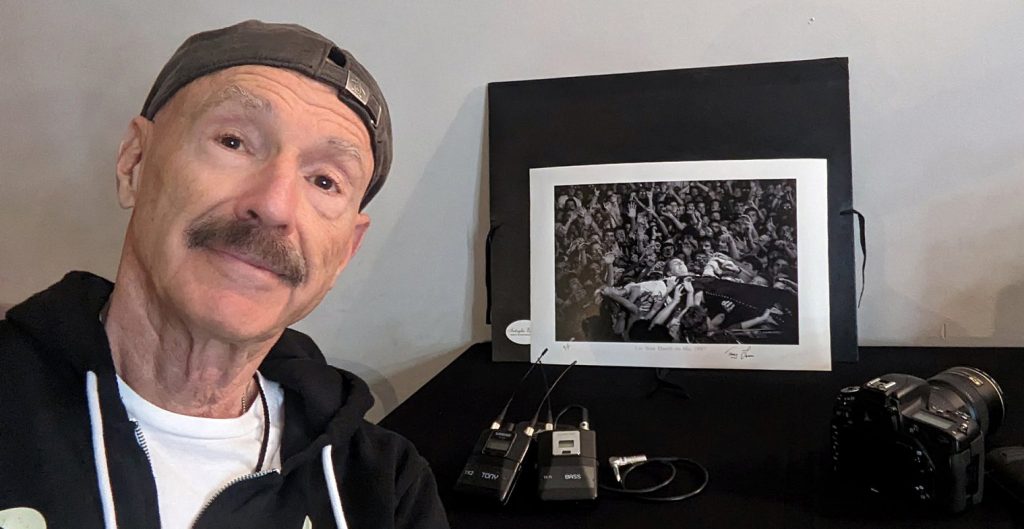

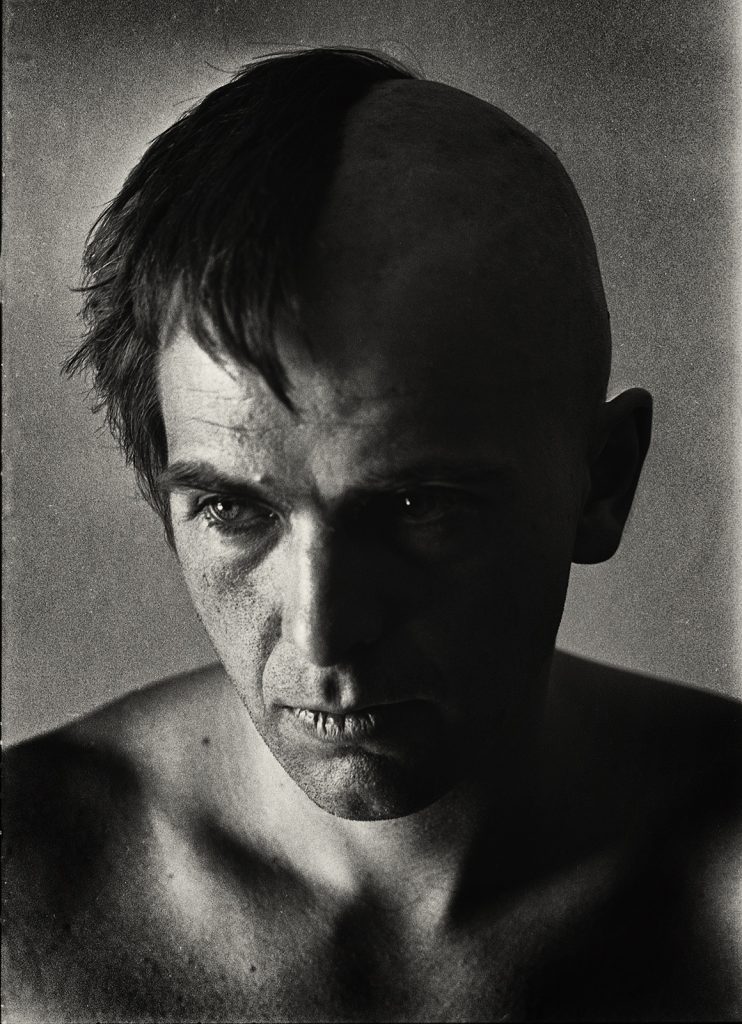

Artist Tony Levin on his music and photography

Excellent interview with Tony Levin, hot off the road from his recent Stick Men tour, and getting ready to embark on a month of touring Europe and England with Peter Gabriel. At 1:07 he discusses his vintage photographs of Peter Gabriel, which are now available as heavy-weight inkjet prints at https://TonyLevinPrints.com

Modern Musicology’s YouTube Channel: https://www.youtube.com/channel/UCk-MlcGy5u3fK1j4bVty1Kw

Find more about Modern Musicology team members:

Rob Levy: https://kdhx.org/shows/show/juxtaposition

Stephanie Seymour: www.therearebirds.com

R. Alan Siler: www.kozmiccreative.com

Anthony Williams: https://watchers4d.podbean.com/

King Crimson Photogravure prints by Tony Levin featured at Haggin Museum exhibition

The legendary Tony Levin shows his limited edition King Crimson intaglio print collection at the Haggin Museum on Feb. 16, 2023. Learn More about this high-quality print collection here:

https://timeless-prints.com/tony-levin-king-crimson-fine-art-prints/

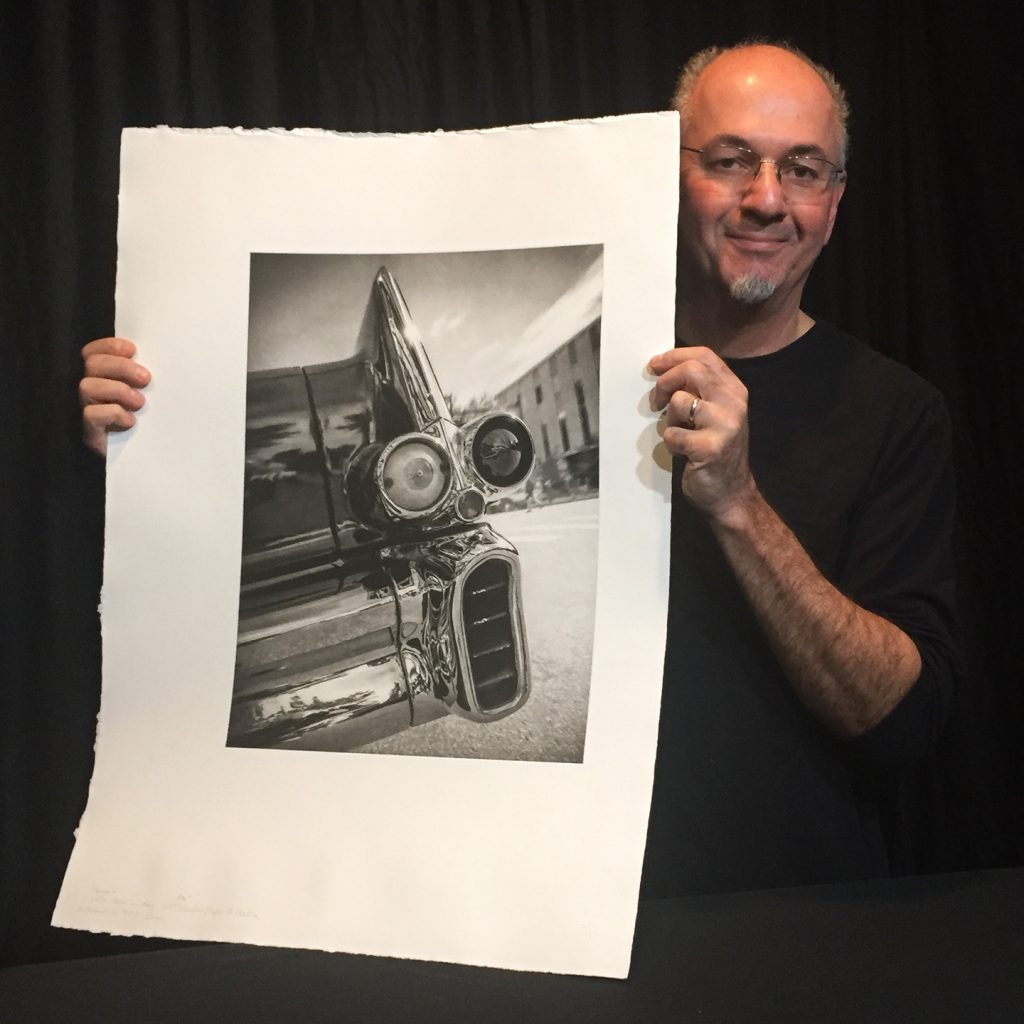

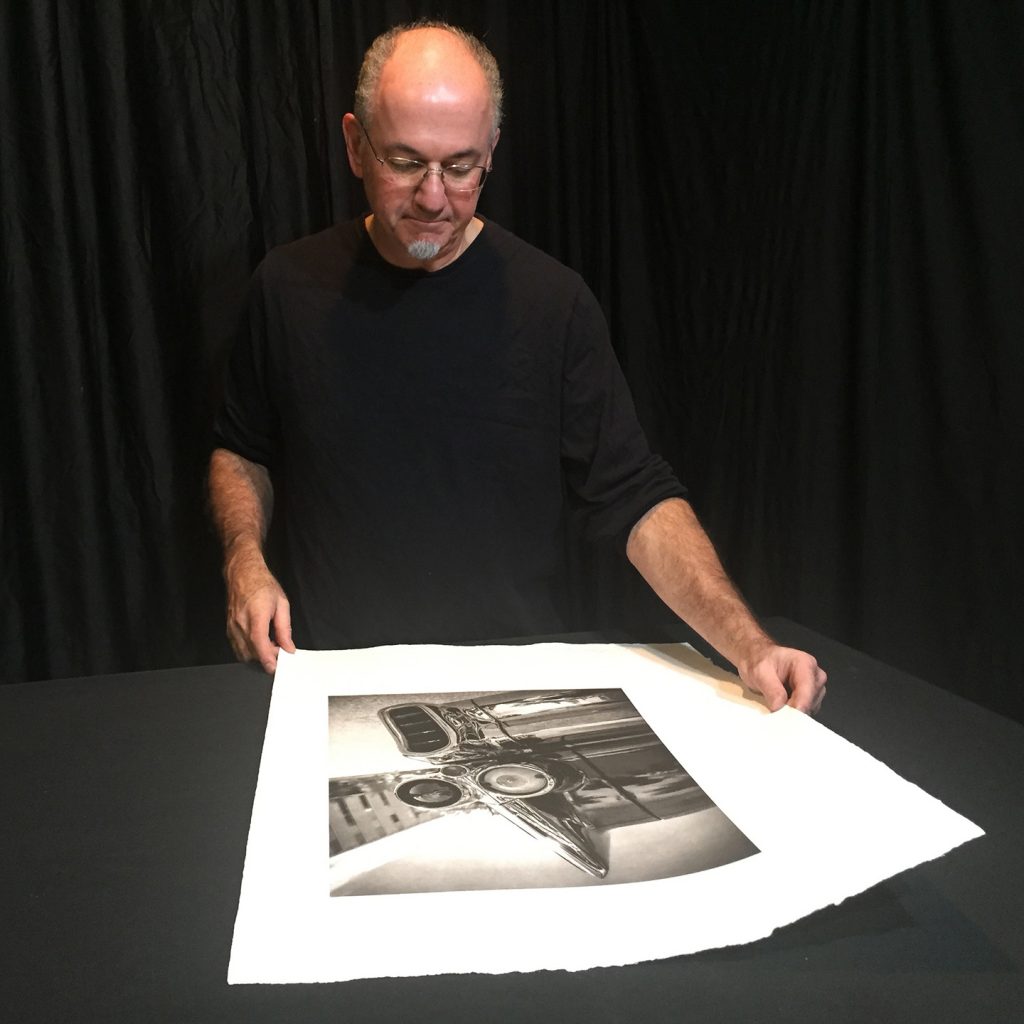

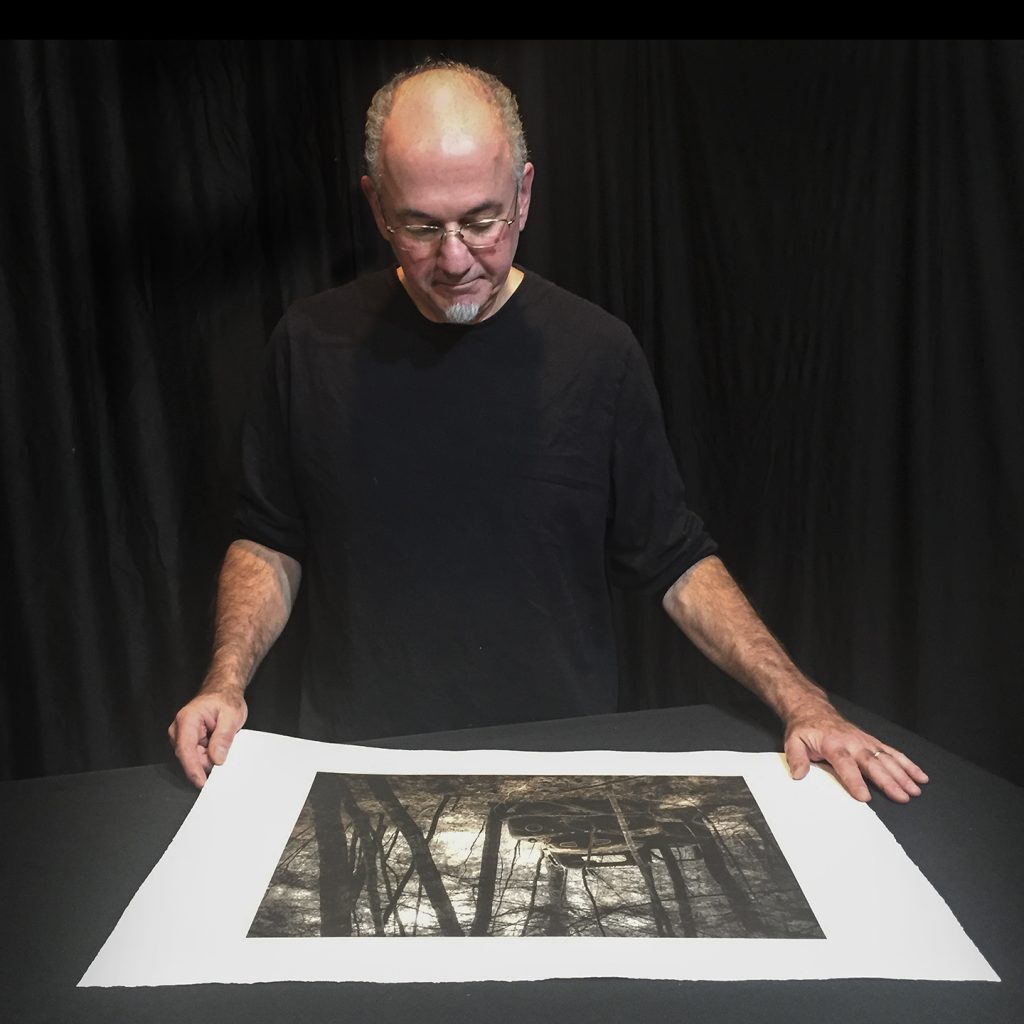

Unboxing New Intaglio Proofs with Artist Jerry LoFaro

Jerry is one of our favorite artists to work with, and in this video you’ll see why. His talents behind the camera and the computer are only exceeded by his capacity for telling bad jokes and cringe-worthy puns in front of it! Photography and videography by Kathleen LoFaro.

“Some of the design details from the late 1950s cars were pretty crazy – they where like chrome & plastic sculptures from a bizarro, futuristic world! However, I think the tail lights of the 1957 Cadillac Coupe de Ville were the most amazing, especially for it’s Mohawk topped, humanoid expression of surprise.

“Some of the design details from the late 1950s cars were pretty crazy – they where like chrome & plastic sculptures from a bizarro, futuristic world! However, I think the tail lights of the 1957 Cadillac Coupe de Ville were the most amazing, especially for it’s Mohawk topped, humanoid expression of surprise.

I first encountered this Ford truck on a neighbor’s property in 1997, shortly after we purchased our home just up the road from them. I thought it was pretty cool, but it somehow didn’t even occur to me to photograph it at the time. However, when the rusty bug finally bit me all these years later, I went out on a hot spring day in 2018 to find it still quietly tucked away, though much further out in the woods than I remembered.

I first encountered this Ford truck on a neighbor’s property in 1997, shortly after we purchased our home just up the road from them. I thought it was pretty cool, but it somehow didn’t even occur to me to photograph it at the time. However, when the rusty bug finally bit me all these years later, I went out on a hot spring day in 2018 to find it still quietly tucked away, though much further out in the woods than I remembered.

I’ve photographed this beautiful barge of a car abandoned in the woods a few times, but “Panic on Main Street” is the first time I encountered a restored vintage model at a car show. I got to the huge Elm Street Classic Car Cruise in Manchester, NH late that September day, and as it was winding down I saw this car getting ready to drive off from it’s spot. I quickly asked the owner if I could take a few shots before he did, and I went right to the back and laid down on the hot pavement to capture this!

I’ve photographed this beautiful barge of a car abandoned in the woods a few times, but “Panic on Main Street” is the first time I encountered a restored vintage model at a car show. I got to the huge Elm Street Classic Car Cruise in Manchester, NH late that September day, and as it was winding down I saw this car getting ready to drive off from it’s spot. I quickly asked the owner if I could take a few shots before he did, and I went right to the back and laid down on the hot pavement to capture this!

Learn more about Jerry’s special edition prints here: https://timeless-prints.com/jerry-lofaro-fine-art-photography/